Programmable Outputs Overview

A programable output allows you to make a dedicated pin in the ECU provide a ground to activate a relay, which can be used to perform a variety of tasks. You can command the Pro-M EFI PCM to provide the ground based on any variable, or any combination of two variables you'd like. Examples of some of the many things you may want to control with a programable output are an electric water pump, or perhaps a secondary fuel pump.

We are sometimes asked why we do not provide more programable outputs. The reason for this is simple. Pro-M Racing does not believe in “Fluff”. Fluff is when a company provides a feature for the sole purpose of being able to say that they are providing that feature. Pro-M Racing will never do this.

I'll explain...

There are several programable outputs in the PRO-M EFI PCM, but only two of them can be user defined. There are good reasons for this. Setting up a programable output properly, for most of the things they are used for, requires code specific to that function within the PCM to operate that output at an OEM level. So, we do this for you, rather than making you figure it out.

A perfect example of this is the output that activates the cooling fan. We could leave this up to you, like the other guys do, but to do this properly requires that several things happen when the cooling fan is active. Compensating for the drag on the charging system for example. And, the cooling fan also needs to come on when the air conditioning compressor comes on. And the combined loads on the engine need to be accounted for. In short, there is a lot to it. Much more than can be described here. So rather than giving you something that works, but doesn't work properly, we do these things for you with dedicated PCM outputs, and with code specific to that function.

Included with every Pro-M EFI system... There are already pre-programed and pre-wired outputs, with proper code for that specific function, for nearly every task you would want. No one else does this!

There are some things that really don't require complicated code, and for those things, we offer you the following:

The user definable programable outputs are “A64 and “B42” The wires leading to the ECU pins are already in your harness. You'll find these wires coiled up in the harness. One is labeled “A64” and the other is labeled “B42”.

These outputs are simple to use and simple to understand. Wiring the outputs is described in the user manual. Some examples of how they might be used and how they might be programed are described below.

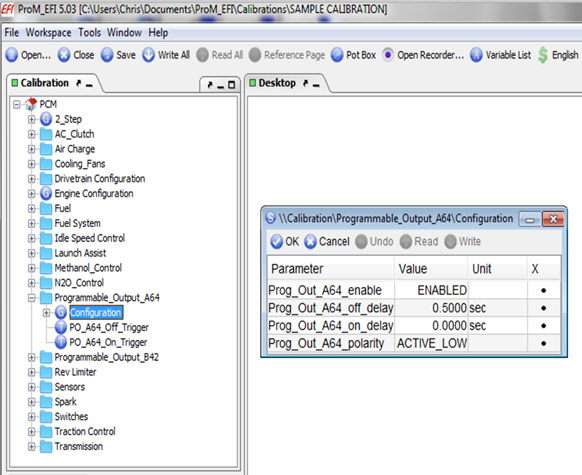

First, simply change “Prog Output Enable” to “Enabled”.

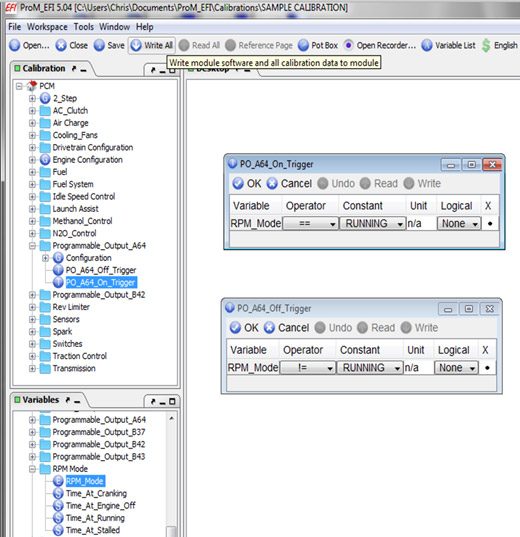

Next, select the variable(s) you want to use to control that output. The variables you choose to activate the output will of course depend on what device you are controlling. In this example we will set up “A64” to run an electric water pump. An example of a variable that would make sense to use here would be “RPM Mode”. In this example, we will program the output to run the water pump any time the engine is running. You can see that we have the “On Trigger” set to activate the output anytime the engine is running. And we have the “Off Trigger” set to deactivate the output when the engine is not running.

In this example, we will set up B42 to run an auxiliary fuel pump. A good reason to do this would be to use two smaller pumps rather than one large pump, which would require a speed controller. The primary pump would be connected to the existing wiring and would operate as usual. The secondary pump would be controlled by the programable output and would become active only when fuel demand requires. This method is infinitely better than using a single pump with a speed controller, since the methods the speed controllers use to determine pump speed are flawed at best.

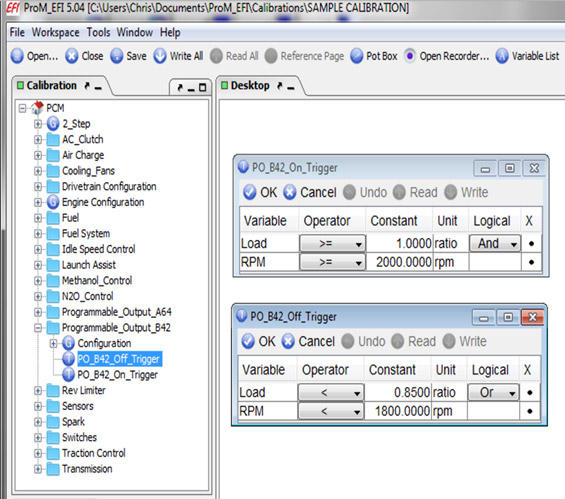

In the example below, the secondary pump will come on when Load is above “1”, and the engine RPM is above 2000 RPM. In short, there must be enough fuel demand to run the secondary pump. The secondary pump will be turned off when Load falls below 0.85 or the RPM falls below 1800 RPM.